CVD graphene: Batch versus Roll to Roll Scale-up

Karlheinz Strobl, Mathieu Monville, Riju Singhal, Samuel Wright, and Leonard Rosenbaum

CVD Equipment Corporation, 355 S. Technology Drive, Central Islip, New York 11722, USA

Abstract

Process development for CVD graphene is typically being done on Cu or Ni substrates in a CVD tube furnace system. Traditionally such systems allow only limited production volume as a result of the size constraints of the substrates that can fit inside a given process chamber. Therefore, in order to commercialize applications enabled by CVD graphene films, new scale up solutions need to be developed that are commercially viable. Roll to roll CVD process systems have been previously proposed and perused by start-up companies as preferred candidates for volume production of CVD graphene material on a Cu foil substrate roll. In this presentation, we will compare the advantages and disadvantages of new patent [1], pending batch processing systems to roll to roll CVD processing systems for volume production of CVD graphene on Cu foils. In particular, we will show that with this novel batch method, a wide variety of CVD graphene production processes can be transitioned to volume production in a more straightforward way. The same hardware platform that enables the processing of multiple Cu substrates in parallel or the processing of a full Cu roll inside a CVD tube furnace can also be used to scale up production for a wide range of 1D and 2D nanomaterials [2].

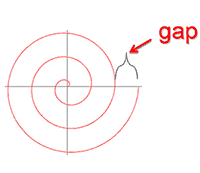

Our EasyGraphene™ and EasyTube® systems (see Fig. 1) comes with different options. Fig. 2 shows the scale up of uniform growth of mm-sized CVD graphene islands on a 300 mm square Cu foil substrate. Fig. 3 shows our “Archimedes Spiral” concept used to increase production volume inside a tube furnace and Fig. 4 shows the estimated roll length capacity as a function of process tube diameter.

References

[1] Scalable 2D-FILM CVD Synthesis patent pending.[2] Scalable CVD Film and Nanomaterials Synthesis, patent pending

Figures

Fig. 4: Volume production potential for Cu foil roll with our patent pending batch processing solution

Submitted to the TNT 2014 Meeting in Barcelona, Spain

Comments are closed.